Laboratory Exhaust Energy Recovery for Valent BioSciences

Laboratories use a substantial amount of energy, including the energy associated with the fume hoods and exhaust. Fume hoods and HVAC systems prevent the inhalation of laboratory chemicals and serve as protection for the lab’s inhabitants. As the air from the laboratory is pulled out and new air is introduced to replace it, there must also be safe, strategic systems in place to ensure the contaminated air is released away from other individuals. A high volume of energy is required throughout this process, but the amount can be lowered by introducing a strategic laboratory exhaust energy recovery system.

The Customer: Valent BioSciences

Valent BioSciences is a cutting-edge research laboratory whose work seeks public health, agricultural, and forest health solutions. Located in Libertyville, Illinois, their laboratory required a strategic solution to meet their energy recovery needs.

The Challenge: Exhaust Energy Recovery

As an advanced research laboratory always pushing forward with new experiments and projects, Valent BioSciences required an HVAC solution that would efficiently and effectively meet their energy recovery needs and could keep up with their high volume of work.

Our focus for this project was to develop a comprehensive laboratory exhaust energy recovery system that works quickly and quietly to reduce the lab’s lost energy and could meet their demands without fail.

The Process

At Gunn & Pegelow, we find tailored solutions to address the unique challenges of our customers in order to implement a system-based solution. The typical process follows four key steps:

- Our team works with the engineering design team to fully understand the design needs, criteria and unique challenges of the customer.

- We develop an iterative and comprehensive solution to address the customers’ pain points and achieve their HVAC goals in the most efficient and valuable way possible. The extensive list of premium manufacturers we partner with allows us to recommend the highest-quality HVAC systems in the market.

- During the bidding process, our working relationships of over 65 years with local mechanical installers allow us to provide the customer with the best value bid offering available.

- After-sale support is paramount to long-term project success. Our dedicated startup and end-user training team facilitates smooth operations for our customers and their personnel until the equipment’s end of life.

The Solution

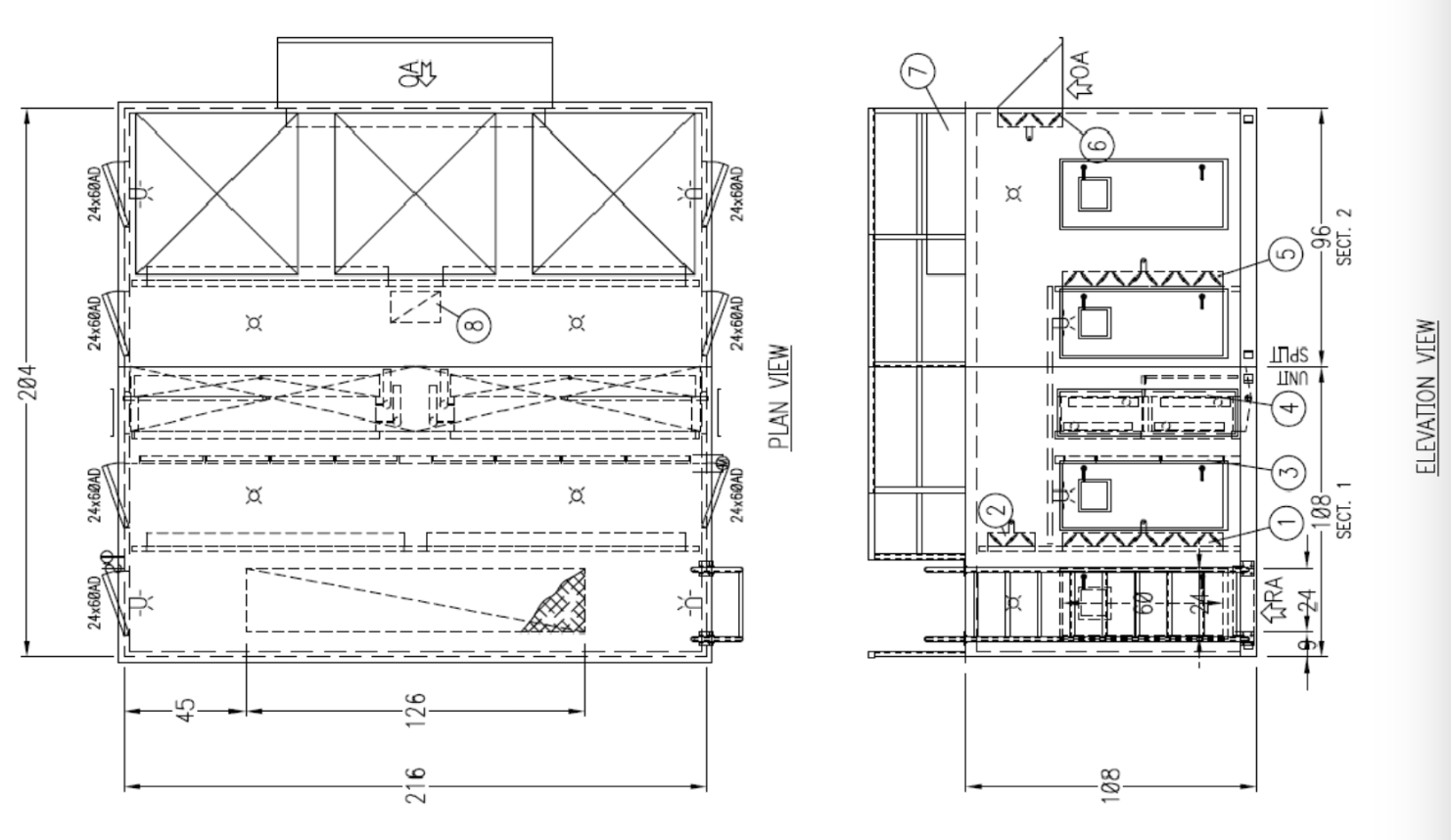

Our HVAC experts turned to the innovative manufacturer of premium fan and exhaust fan systems Strobic Air Technologies to build our solution. The system detailed below includes three Strobic Air TriStack Fans, Model TS4. Two fans are utilized for total exhaust while one fan is on standby.

The total exhaust of this system is 42,650 cfm at 6.2” pressure.

Fan Details

- 40 HP, Direct Drive, 1200 rpm, VFD compatible, TEFC mill & chemical duty motors with shaft grounding, disconnects, 460/3/60

- VFD’s mounted and factory wired

- Combination Silencer/Windband/Nozzle

- Epoxy coating, 12 mils thick

- Low leakage fan isolation damper with electric two-position damper operator

- Rated for AMCA “C” spark-resistant construction

ERU/ Plenum Details

- One custom plenum

- Energy recovery coils, with coil face and bypass dampers and actuators

- MERV 8 filters

- Access ladder

- Safety rails

Additional System Details

Warranty – The warranty for the complete fan, motor, bearings, and drive train is seven-years limited. ERU plenum, dampers, etc. carry a standard 18-month warranty.

Noise – The sound level of the system at 50’ meets the neighborhood requirement of 57 dBa that was listed on the Project Drawing Specification.

Shipping and Weight – ERU ships in two sections (the fans ship separately). The heaviest piece weighs 12,500 pounds.

Final Results

The system we implemented at the facilities of Valent BioSciences empowers their team to conserve energy through our custom plenum and innovative tri-fan system. Designed to maximize energy recovery, this system delivers a substantial impact on the Valent team’s energy efficiency.

Built with Valent laboratory’s commitment to progress in mind, our system includes a standby fan that ensures continuous operations. If one of the two active exhaust fans fails, the standby fan seamlessly takes over, allowing the Valent team to maintain smooth operations without interruption.

In collaboration with Marcraft, who constructed the massive structure housing the energy recovery coils, our system provides Valent with the robust exhaust energy recovery strategy they need. This setup not only reduces energy consumption but also helps maintain a safe, contaminant-free environment, enabling the Valent team to focus on their innovative projects with confidence.

Contact Gunn & Pegelow for Expert HVAC Solutions

Unlock the full spectrum of HVAC expertise with Gunn & Pegelow. Whether you’re involved in automotive retail, commercial spaces, or diverse projects, we offer unparalleled support across various dimensions. We pride ourselves on delivering solutions that go beyond generic approaches, providing a customized touch to every project. From conceptualization to execution, our team is dedicated to making your HVAC startup experience efficient and problem-free.

Gunn & Pegelow has a proven track record of contributing to the creation of exceptional spaces, as showcased in the Harley Davidson Wrigleyville project in Chicago, IL. Our team is readily available to address any queries, troubleshoot issues, and ensure the optimal performance of your HVAC system. With us, you have a reliable partner throughout the lifespan of your project.

Let us bring our expertise to your project, ensuring not just functionality but also a transformative impact on your HVAC solutions.

Contact us today to elevate your next project with our comprehensive HVAC solutions.